In an effort to reshape the future of electric vehicles (EVs) in India and globally, Tata Group and Vedanta have teamed up to develop a breakthrough technology: Silicon Carbide (SiC) chips.

These advanced semiconductors are set to enhance the range and efficiency of electric vehicles, overcoming one of the major challenges in EV development — limited battery range and power conversion efficiency.

This tiny yet powerful technology promises to boost EV performance, reduce charging time, and help achieve cleaner mobility.

Introduction: A Game-Changer for Electric Vehicles

As the world shifts towards electric mobility, the need for better-performing EVs is more critical than ever. One key aspect of EV performance is the efficiency of energy conversion systems, which manage how electricity from the battery is used to power the vehicle.

Traditional power electronics, made of silicon semiconductors, are reaching their performance limits in this regard. This is where Silicon Carbide (SiC) chips come in, offering enhanced efficiency and higher energy conversion rates, crucial for longer driving ranges and faster charging times.

The partnership between Tata Group and Vedanta aims to produce these SiC chips locally, reducing reliance on imports and positioning India at the forefront of global semiconductor production for electric vehicles.

What Are Silicon Carbide Chips?

Silicon Carbide is a compound semiconductor material that combines silicon with carbon atoms. It offers superior thermal conductivity, voltage handling, and switching speeds compared to traditional silicon chips.

The key difference lies in its ability to operate at much higher temperatures and efficiency in high-power applications, such as those required for electric vehicles. In an EV, SiC chips are used in power inverters and DC-DC converters — essential components that manage the conversion of power from the battery to the motor and other vehicle systems.

The efficiency of these components is directly tied to the performance of the EV, influencing key factors such as range, acceleration, and battery life.

Advantages of Silicon Carbide for EVs:

- Higher Power Efficiency: SiC chips reduce energy loss during conversion, resulting in more efficient use of battery power.

- Increased Range: More efficient power systems mean EVs equipped with SiC can go further on a single charge.

- Faster Charging: SiC allows for faster charging systems by reducing heat generation, enabling higher charging voltages and currents.

- Reduced System Size: SiC’s efficiency allows for smaller power components, reducing the weight of the vehicle.

The Tata-Vedanta Collaboration: A Strategic Leap in Semiconductor Manufacturing

The collaboration between Tata Group and Vedanta aims to produce Silicon Carbide (SiC) chips locally in India, as part of a broader effort to bolster India’s semiconductor manufacturing ecosystem.

Through this initiative, the companies aim to reduce India’s dependency on foreign semiconductor imports, while contributing to the government’s India Semiconductor Mission (ISM).

Tata’s Commitment to Electric Mobility

Tata Group, a leader in the Indian automotive sector through its subsidiary Tata Motors, has been aggressively pushing its electric vehicle portfolio. Tata Motors has already launched several EV models, including the Tata Nexon EV and Tata Tigor EV, and is planning to launch new electric vehicles across different segments.

By incorporating SiC chips into their vehicles, Tata aims to enhance their EVs’ performance, offering customers more range, faster charging, and a better overall driving experience.

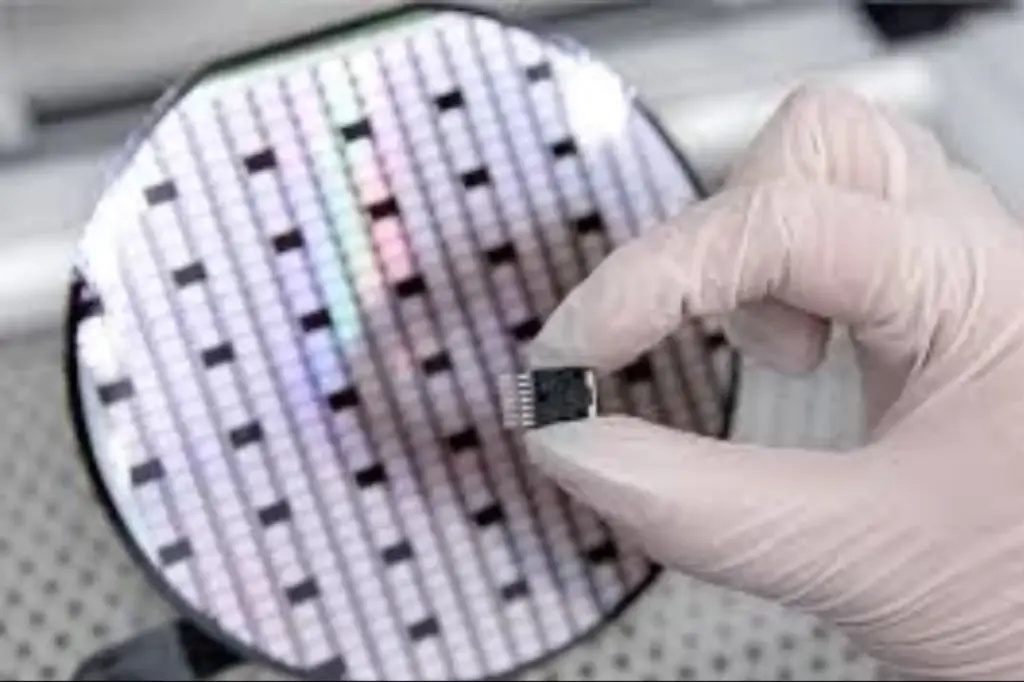

Vedanta’s Role in Semiconductor Manufacturing

Vedanta, traditionally known for its work in natural resources, is making a strategic shift towards the technology sector. The partnership with Tata brings Vedanta’s extensive industrial expertise into the semiconductor manufacturing space, aiming to produce SiC wafers and related power electronics.

The move will not only cater to India’s growing electric vehicle market but also meet the global demand for power-efficient components used in industries ranging from renewable energy to aerospace.

Made in India: Strengthening the Semiconductor Ecosystem

This collaboration underscores the Indian government’s push for self-reliance in semiconductor manufacturing. Under the India Semiconductor Mission, India aims to establish itself as a major player in the global semiconductor supply chain.

The production of SiC chips is expected to foster local innovation, increase employment in the high-tech sector, and reduce India’s import bill for high-value technology.

How SiC Technology Boosts EV Performance

1. Increased Driving Range

The key benefit of Silicon Carbide chips is their ability to reduce power loss during conversion. In traditional silicon-based power systems, significant energy is lost as heat, reducing the efficiency of energy conversion and affecting the vehicle’s range.

SiC chips, on the other hand, operate at much higher temperatures and handle higher voltages, reducing energy wastage. As a result, EVs using SiC technology can achieve up to 10% more range on a single charge.

This is especially significant in India, where EV adoption is growing rapidly, but range anxiety remains a barrier. SiC chips directly address this concern by making EVs more reliable and ensuring that consumers can travel longer distances without the fear of running out of charge.

2. Faster Charging Time

Faster charging is another major advantage of SiC semiconductors. EVs with SiC-based power electronics can handle higher charging currents and voltages, reducing the time required to charge the vehicle. This faster charging capability is a game-changer for consumers who are used to the slow charging times of traditional EVs.

For example, a SiC-equipped charging system could potentially cut charging time by up to 30-40% compared to traditional systems. In a country like India, where charging infrastructure is still in its nascent stage, faster charging will encourage more consumers to switch to electric mobility.

3. Improved Efficiency and Durability

Silicon Carbide chips are more thermally stable and durable than silicon-based counterparts. This makes SiC power systems less prone to degradation over time, ensuring longer lifespans for EVs.

Additionally, the ability of SiC chips to operate at high temperatures means that the vehicle’s cooling systems can be made smaller and more efficient, reducing overall vehicle weight and further improving performance.

Tata-Vedanta’s Impact on India’s EV Market and Economy

Economic Growth and Job Creation

The development and manufacturing of Silicon Carbide chips in India will drive economic growth in several ways. It will create high-tech jobs in semiconductor manufacturing, research and development, and related fields.

Additionally, India’s electric vehicle market will benefit from a more affordable and efficient supply of power electronics, which will lower the cost of EVs and make them more accessible to a broader section of society.

As India continues its shift towards sustainability and clean energy, the growth of the SiC semiconductor industry will help build the infrastructure needed to meet the country’s ambitious EV adoption targets.

The local production of SiC chips will also reduce India’s dependence on foreign suppliers, giving the country a competitive edge in the global EV and semiconductor markets.

Impact on Global Semiconductor and EV Markets

India’s role in the global SiC chip market will also evolve as Tata and Vedanta ramp up production. As demand for electric vehicles increases globally, the need for high-performance semiconductors, especially Silicon Carbide, will grow exponentially.

India’s ability to produce these chips locally will place it in a strong position to capitalize on the global demand for EV power electronics and contribute significantly to the electric mobility revolution.

Challenges and the Road Ahead

While the potential benefits of SiC chips are clear, there are still challenges ahead. The production of Silicon Carbide wafers is more complex and expensive than traditional silicon-based chips. Scaling up production to meet the rising demand for these chips, both locally and globally, will require significant investment in infrastructure, research and development, and skilled labor.

Additionally, India’s semiconductor ecosystem is still in its infancy, and while the government has laid out clear plans for growth, global competition from established semiconductor players like Taiwan, South Korea, and China will present challenges.

Related Links

Flying Taxis in India? Successful Trials Show You’ll Soon Travel Without Petrol or Diesel.

Can You Get Free Solar Panels in the USA? Check If You Qualify for This Government Grant

A Bright Future for India’s EV Industry

Tata and Vedanta’s development of Silicon Carbide chips marks a transformative moment for the Indian electric vehicle sector. These tiny chips promise to deliver major improvements in efficiency, range, and charging speed, making electric vehicles more accessible and practical for Indian consumers.

The collaboration between these two industrial giants is also a crucial step towards establishing India as a global hub for semiconductor manufacturing, positioning the country at the forefront of the electric mobility revolution.

With continued investment in research, manufacturing, and infrastructure, India’s EV ecosystem could see unprecedented growth, creating a cleaner, greener future for the nation and driving sustainable economic development.